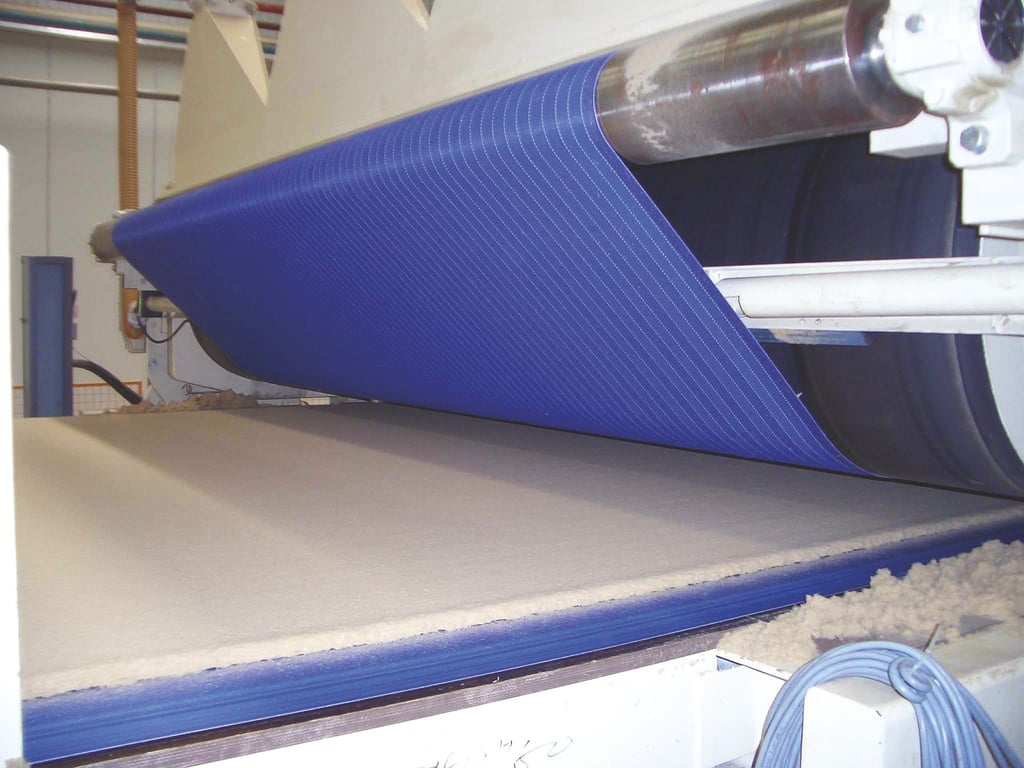

Process Belts for Deaerating MDF and Chip Mats in the Timber Industry

Fabristury’s ventilation belts are expertly woven as hybrid meshes, combining polyester and bronze for superior performance. Their unique weave structure ensures optimal deaeration of the product cake, while the interwoven bronze wires—integrated through our Conducto® technology—provide permanent electrostatic discharge in compliance with ATEX standards.

Our Conducto® ventilation belts are synonymous with high quality, offering exceptional mesh strength and running properties thanks to advanced weaving technology. These belts are designed to meet the rigorous demands of the timber industry, delivering reliability and efficiency in every application.

Key Properties:

Excellent product cake deaeration for enhanced efficiency

Permanent electrostatic discharge compliant with ATEX standards

Optimum running properties for smooth operation

Custom seams tailored to specific process requirements

Dimensional and form stability with the necessary flexibility

Fray-resistant edges due to specialized edge treatment

Trust Fabristury to provide ventilation belts that combine durability, performance, and safety, ensuring superior results in your MDF and chip mat production processes.

Partner with Fabristury Today!

Ready to elevate your operations with innovative, sustainable, and tailored solutions? Contact Fabristury now to discover how our cutting-edge mesh and filtration technologies can meet your unique needs. Let’s collaborate to drive efficiency, enhance performance, and achieve your goals.